Description

TraceWay Max allows you to label products that are not yet subject to legal requirements for mandatory labeling. At the same time, our solution covers all levels of the labeling system: from the development and supply of equipment and software to the generation of codes and tracking their current statuses on a centralized server.

Thanks to voluntary labeling, we optimize internal logistics, make it transparent, and protect your products from counterfeiting. Due to this, the costs of implementing TraceWay Max are quickly reimbursed.

Leading enterprises for the production of fertilizers and automotive components are already cooperating with us.

TraceWay Max — voluntary labeling system of products. We optimize internal logistics, make it transparent, and protect your products from counterfeiting.

For product categories:

Agrochemicals

Any others that are not subject to mandatory labeling

A comprehensive solution

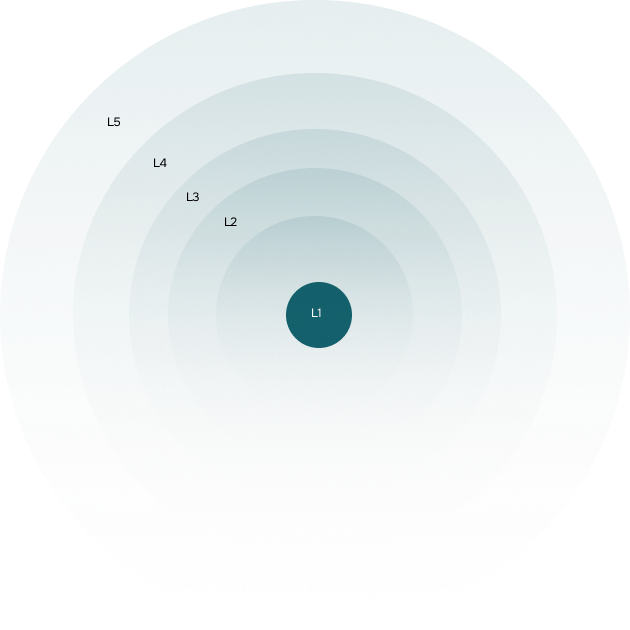

There are five levels of the marking system:

- L1: equipment in the workshop,

- L2: Software for managing equipment in the workshop,

- L3: Software for managing the labeling process in the whole enterprise,

- L4: integration with other IT systems of the enterprise, for example, 1C,

- L5: processing system, for example, "Honest sign".

If the product is included in the list of mandatory labeling, then the L5 processing system works centrally. In this case, the manufacturer's task is to find a contractor to implement the L1—L4 levels. It is not difficult to do this: there are many offers on the market.

But if mandatory labeling is not applied to products, it is difficult to find a solution that would ensure work at all five levels. And then Raceway Max comes to the rescue. This is a unique product.

We have built an infrastructure for generating labeling codes and processing them. Processing provides centralized storage of code data on servers Traceway Max. This allows you to get data about a specific product while outside an information network where the usual Raceway interfaces may not be available due to with a security policy.

Organic integration into the IT landscape

TraceWay has an API for easy integration with ERP and WMS systems.

This allows you to:

-

1

work from your familiar environment. For example, to order marking codes in the CPS from 1C, without logging into TraceWay,

-

2

automatically synchronize directories in the background, rather than running them in two systems in parallel,

- 3

work with TraceWay reports in your system.

We have already successfully integrated TraceWay with 1C, SAP, Axapta for several customers.

Our product also provides integration with other customer software products via the API or using the TraceLink network.

We are ready to work with Russian and foreign customers.

Own business scenarios

Voluntary labeling of goods allows you to create your own business scenarios.For example, you can connect distributors to the labeling system and track the movement of each product instance. At the same time, you determine the set of operations that are subject to accounting. Due to all this, labeling costs are quickly reimbursed.

Verifying the authenticity of the product

Unique labeling codes protect your products from counterfeiting. It is easy to verify the authenticity of the product using the website or mobile application. And you choose who you grant the right of verification to: your employees, representatives of the distributor, retail or end consumers.

If a fake is detected, our contact center will consult the deceived buyer. All cases of counterfeit detection will be recorded in the system automatically with reference to the region and time of authentication.

Transparency of the product chain

TraceWay Max tracks the history of each item in the following stages:

- acceptance of raw materials,

- production and labeling of products,

- packing and palletizing,

- moving to the warehouse,

- shipment from the warehouse.

In addition, monitoring of intermediate operations is available: sampling for inspection, pallet reshaping, etc.

You can easily find out what is happening with the product, find out the stock balances, and evaluate the effectiveness of internal logistics. In case of a defect, you can find out from which batch of raw materials, by whom and on which line the product was released.

You can also monitor the movement of your product after shipment from the warehouse. Any links of the distribution chain are connected to TraceWay Max: logistics center, distributor, retail. You own the information:

- about the availability of stocks at the distributor/in a specific region,

- about the volume of shipments or sales,

- about the routes of movement of goods,

- about the history of movement of a particular product instance.

We help you plan production based on objective and operational data.

Round-the-clock support

TraceWay has a 24/7 technical support service. Qualified first and second line specialists work here. We guarantee a quick response to your request.

Readiness for mandatory labeling

В ближайшее время правительство планирует охватить маркировкой большинство отраслей промышленности.

By the time the product category is connected to the mandatory labeling, TraceWay Max users will have already installed the necessary equipment and debug the processes. Therefore, the transition from voluntary labeling to mandatory labeling will be easy and painless. Plus, data from TraceWay Max to the TraceWay version will be transferred losslessly.

Look at the examples

We make internal logistics as transparent as possible.

R–Pharm was the first company in Russia to voluntarily introduce drug labeling using the TraceWay system. Her experience was taken into account when introducing mandatory labeling